About Us

Fox Marble Holdings plc is a dimension stone company focused on quarrying in the SW Balkans and processing in Kosovo. It is listed on the AIM market of the London Stock Exchange (AIM:FOX).

Fox Marble completed its first processing facility in Kosovo in 2018. This enables the Group to process marble blocks into finished slabs and cut to size pieces for customers around the world. The Group's goal is to establish itself as the industry leader in decorative stone from Kosovo and Southeast Europe, bringing the highest quality stone to the market at highly competitive prices. To this end in October 2016 Fox Marble announced the launch of Stone Alliance LLC. Fox Marble believes that this U.S registered company has the potential to dwarf its parent. It is expected to have more than 40 quarrries and 3 processing plants.

our journey

Fox Marble was founded by Chris Gilbert and Dr Etrur Albani in 2011 to exploit the extensive high quality, and in many cases unique, marble and dolomitic limestone reserves in Kosovo where the dimension stone industry had lain dormant for many decades. The aim from the outset was to own and operate quarries, process the stone and sell stone block, transformed stone and the bi-products of processing. A secondary objective was to introduce a new industry and type of business governance to Kosovo..

Following extensive research, the company acquired rights and mining licences to five quarries at Rahovec (three quarries including Malishevë and Cervenillë), Syriganë and Pejë. These quarries promised an exciting palette of colours from white, through a variety of greys to red and gold.

Fox Marble listed on the AIM of the London Stock Exchange in August 2012 raising the capital needed to equip, develop and operate its quarries and build its processing plant. It remains the only AIM listed dimension stone company and is the first publicly listed company from anywhere in the world to build its operations predominantly in Kosovo. The company is a trail blazing pioneer on many levels.

The initial focus was on opening its quarries. Guided by its Italian quarry strategist and highly skilled Italian quarrymasters, a workforce was recruited and trained. Few of the workforce had any previous quarry experience. Access roads, some of them substantial pieces of civil engineering in their own right, were constructed and services installed. Quarry sites and their adjacent block parks were mapped out in detail and cleared. Only then could actual quarrying commence.

Dimension stone quarries take time to open in a way which balances short-term yield and long-term potential. The geology has to be investigated in detail and adjustments made to the orientation of excavations. Three operating seasons (these are March/April to December/January in Kosovo and North Macedonia depending on the length and severity of the winters) to bring a quarry into consistent production is normal. Fox Marble reduced that time scale with a herculean effort at all its sites but developing a top quality dimension stone quarry is still more of a painstaking than a spectacular process.

Once the overburden has been removed, excavation is by precision drilling and cutting in order to preserve the integrity of the raw material. The target output is large uniform stone blocks (up to a maximum of 25 tonnes in Kosovo because of transport regulations) and the faster more destructive quarrying techniques of the aggregates industry are simply not an option. Cutting the blocks and removing them creates the stone ‘benches’ (see images above) – giant steps that are the defining visual characteristics of dimension stone quarries.

As in most quarries, the material from closest to the surface in the Fox quarries has, for hundreds of thousands of years been subjected to the effects of weathering and the action of plant roots breaking up the uniformity of the stone and producing holes, cracks and sometimes discolouration. Furthermore, both Kosovo and North Macedonia are seismically active areas and this adds to the cracking in the surface layers. The higher quality stone, more compact, uniform and with fewer cracks and holes comes from deeper in the quarries.

Even the surface material may have commercial value. Fox Marble has stockpiled the better surface stone from each of its quarries to await the installation of a tile processing line in its factory. Much of it is perfect for small cut to size items such as tiles and anything which does not make the grade for that will eventually be crushed for gravel or powder.

Quarrying in Kosovo over the last 3 years has more than borne out the optimism of the early survey work. But the Company recognised early on that a whiter marble than its Kosovo quarries were yielding would significantly enhance its portfolio. Neighbouring North Macedonia had exactly what was needed. This world-renowned material occurs in deposits running for more than 50 km through central and southern North Macedonia and the company was fortunate to be able to acquire, with the help of a local partner, a large concession just to the north of Prilep, North Macedonia's answer to Carrara. It has rights to two quarries and has been extracting marble commercially since 2014.

Once work on opening the quarries had begun, Fox turned its corporate attention to its first processing factory. Replacing expensive and logistically complicated processing in Italy with significantly less expensive and more agile processing in Kosovo was always a cornerstone of company strategy.

The factory was designed in Italy around mostly Italian machinery. The building itself, in a prominent yellow, was purchased and shipped from Greece whilst all the construction work was undertaken, to exacting standards, by local companies. As soon as the building shell was complete a local artist was commissioned to paint the company name on the side of the building in letters large enough to be visible many km away and, importantly for such a pioneering investment, to be visible from aircraft taking off and landing from the nearby international airport. Those who have not seen it often assume that the name must have been Photoshopped!

The factory was completed in stages under the supervision of Italian and, latterly, Spanish specialists. The first of the vast gangsaws, which cut stone blocks into slabs, began cutting right at the end of 2016. The slab polishing line and the epoxy resin line became fully operational in late summer 2017 and the first exports of finished stone slabs to the US came shortly afterwards. Sophisticated machinery to produce stone tiles and other cut to size stone products was commissioned in 2018. Landscaping the factory site took place in 2019. An extensive tree and shrub planting programme around the site in 2019 improved the look of the site but it was the arrival of a new and highly skilled Spanish management team that has really transformed productivity.

World Marble Market

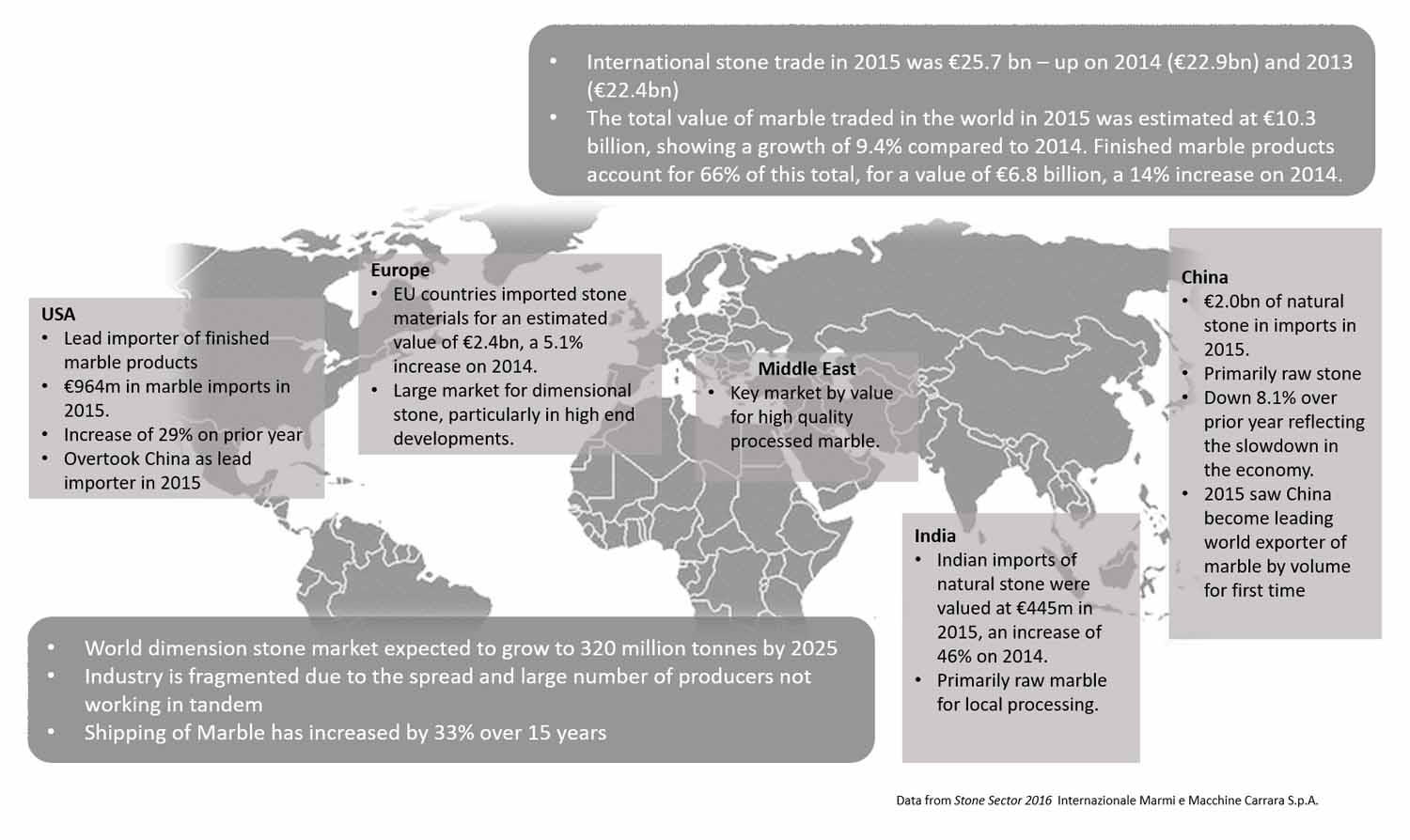

Driving Fox Marble is a growing global dimension stone market. It is competitive and dominated by family-owned companies. Fox Marble aims to bring a new style of business discipline and governance to that market and is in a unique position to sell large volumes of highly desirable fine quality dimension stone at prices competitors will struggle to match.

The market varies from country to country, region to region. In China and India for example, with low local processing costs, the market is for unprocessed stone blocks. Europe, on the other hand wants stone slab and cut to size as does the Middle East. The US is interested in transformed stone - cut to size taken to the next decorative level.

Kosovo was once an isolated inland Yugoslav province. Today it has a motorway to Albania which has cut the road transport time to the Albanian container and ferry (to Italy) port of Durres by two thirds since 2009. Connecting roads to the trans-Balkan motorway network are currently congested and slow but a US/Turkish built motorway is getting closer to Macedonia by the day. It should connect in 2018. Meanwhile, plans are already advanced to upgrade the rail link to Thessaloniki and later into Serbia. Indeed, the Fox factory has been sited expressly to take advantage of the rail link to Greece and the company is now pushing to have a rail spur built to the new Lipjan industrial zone in which it is the first resident.